Condition Monitoring

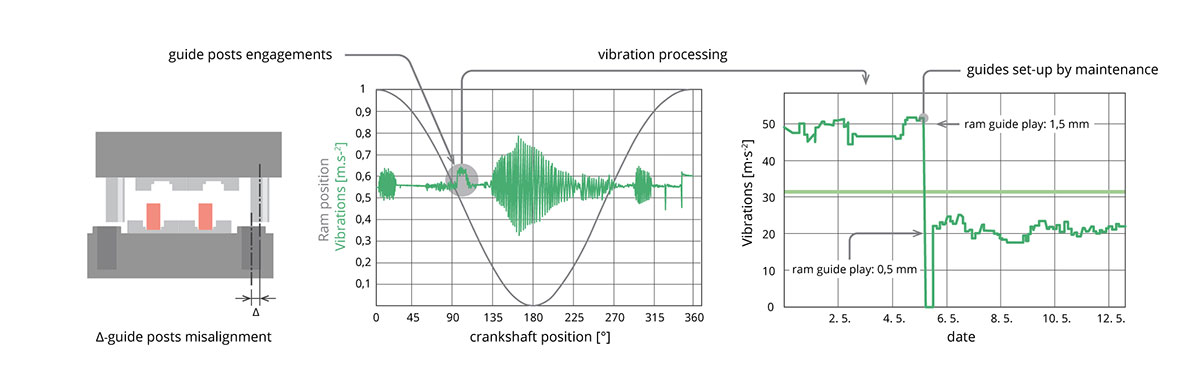

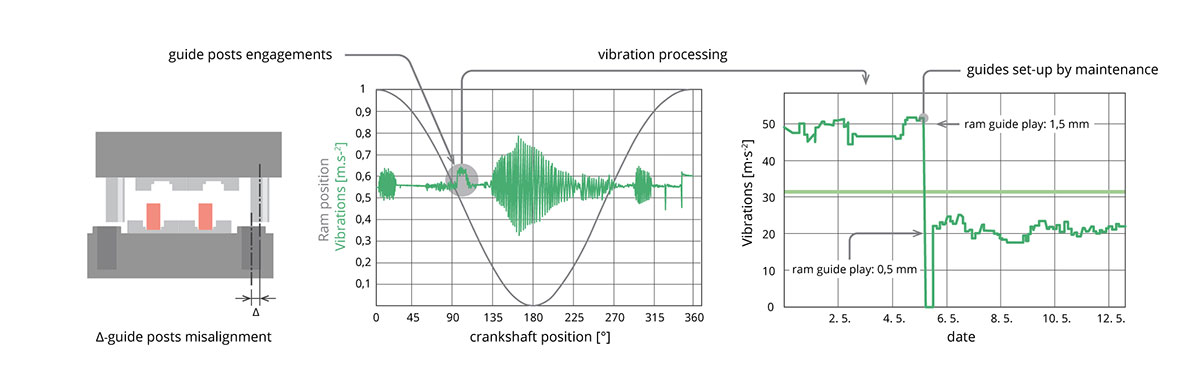

Several machine parameters, for example, the guide clearance or the planarity of the bed and ram surfaces or the degree of wear on the bolster surface can only be checked during downtime of the machine. If these parameters are not known a reduced quality of the forgings may have to be accepted or initially small signs of wear and tear may lead to major and expensive damage on the bolster and the machine. Real-time monitoring of these parameters, however, leads to an early detection of abnormal conditions. Various sensors are used for this task. These sensors are not new in principle, but the amount of data they produce needs to be transmitted, stored and analyzed which has only become possible with modern technology, both hardware and software.

The following parameters are monitored:

The following problems can be detected:

A qualitative change of these parameters which exceeds the set limits will be displayed in a web application on any device (HMI, PC, mobile).

For more details please visit the webpage of our partner 4dot http://4dot.cz/

The following parameters are monitored:

- Ram guide clearance

- Tilting of the ram, non-parallelism of the dies

- Correct clamping of the bolster

- Forging load for monitoring of the deformation forces and to protect the press from overload

The following problems can be detected:

- Excessive guide clearance

- Incorrect clamping of the dies and/or bolster

- Crack initiation in bolster

- Excessive wear of the surfaces of the press bed, ram or bolster

A qualitative change of these parameters which exceeds the set limits will be displayed in a web application on any device (HMI, PC, mobile).

For more details please visit the webpage of our partner 4dot http://4dot.cz/